As an electronics manufacturing services firm with core competencies in printed circuit board (PCB) assembly and PCB layout, ACDi provides full turnkey solutions. We take pride in our clients’ confidence in our quality standards and quick turnaround time.

Having a full-service, end-to-end electronics manufacturing services provider is universally the most efficient way to successfully implement your build, from conceptualization to execution—and that begins with a solid design by a PCB layout professional.

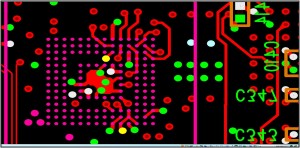

PCB Design Services

Utilizing client specifications, ACDi provides layout and design services through the use of the latest tools and standards in the industry. In addition, ACDi’s design team provides the added benefits from design for manufacturability (DFM), design for assembly (DFA) and design for testability (DFT) to further validate designs and prevent delays during production.

Our team of designers has over a century of combined experience on every kind of board, from small two-layer boards to high-speed, multi-layer designs, and everything in between. In fact, in 2018 we had the milestone distinction of reaching 10,000 PCB layouts and marked the achievement with a donation to a local robotics club.

PCB Assembly & Manufacturing

One of the benefits of having PCB layout services in-house at the electronics manufacturing plant where you plan to assemble is pretty simple—communication. If there are any questions about the integrity of the design or the board has issues at test, the test engineers have direct access to the PCB designer, typically solving the issue without the customer’s involvement. Additionally, the PCB layout team has the ability to see the product they designed being built on the manufacturing floor, which also allows them to communicate back any ideas for layout improvements.